Different finishes available for stainless steel sheets and plates and their applications

Stainless steel sheets and plates come in various finishes, each with its own unique properties and applications. Here are some of the most common finishes and their uses:

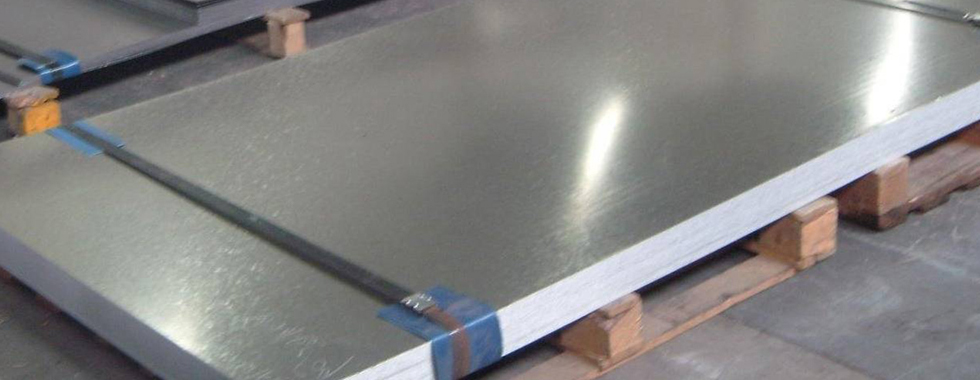

No. 1 Finish - This is a hot-rolled, annealed, and pickled finish that is coarse and dull. It is primarily used in industrial and architectural applications, such as flooring and machinery.

No. 2B Finish - This is a cold-rolled, annealed, and pickled finish that has a smooth, reflective surface. It is commonly used for decorative purposes, such as kitchen appliances, jewelry, and trim.

No. 3 Finish - This is a ground finish achieved by using progressively finer abrasive material. It has a semi-reflective appearance and is often used for architectural and decorative purposes.

No. 4 Finish - This is a polished finish achieved by using a 120-150 grit abrasive. It has a brushed appearance and is commonly used for kitchen equipment, architectural trim, and signage.

No. 8 Finish - This is a mirror-like finish achieved by using a 320 grit abrasive. It is often used in decorative and architectural applications, such as mirrors, column covers, and wall panels.

Hairline Finish - This is a finely brushed finish that resembles the grain of hair. It is commonly used for decorative purposes, such as elevator doors, escalators, and trim.

Satin Finish - This is a brushed finish that has a soft, silky appearance. It is often used in decorative and architectural applications, such as handrails, door hardware, and lighting fixtures.

Overall, the choice of finish depends on the desired aesthetic, as well as the intended application and environment. Each finish has its own unique characteristics and properties that make it suitable for specific uses